Intelligent Vision

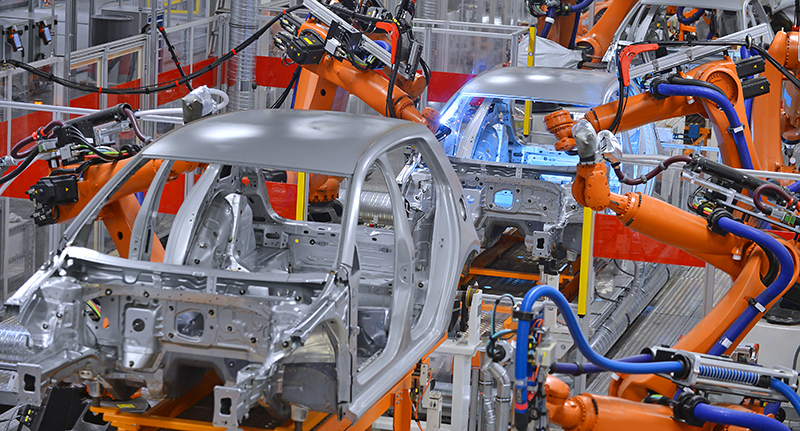

Our Machine Learning technology applied to intelligent cameras allows us to automate industrial processes in manufacturing, recycling, logistics, quality and others. Infrared, thermographic, 3D, thermal, laser and other cameras are designed to work with our IIoT artificial vision platform for the control and automation of production processes.

This automation allows the improvement of production and quality, which has a direct impact on efficiency and profitability, but also on the safety of resources and people, as well as on the quality of products.

These artificial vision cloud solutions are applicable to any sector and are currently present in sectors such as Energy, Automotive, Food&Beverage, Security, Chemical, Pharmaceutical and others.